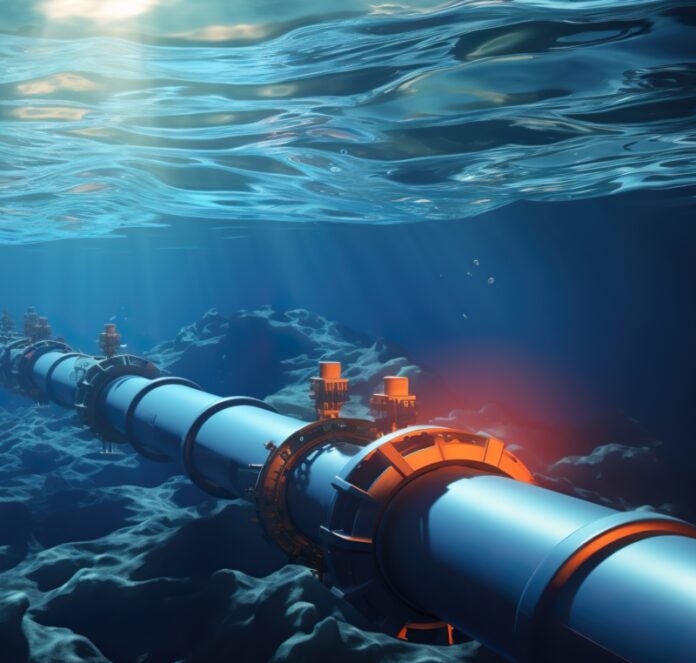

Subsea pipeline reviews are essential in guaranteeing the submerged framework’s honesty and security. These inspections have traditionally been time-consuming, expensive, and necessitated extensive human resources and specialized equipment. On the other hand, underwater drones have revolutionized the process, providing significant advantages in terms of efficiency, accuracy, and cost-effectiveness.

“Subsea pipeline inspection is critical to the safe transfer of oil and gas from off-shore rigs to storage and processing facilities on land. As perhaps the costliest and most widely installed component in subsea infrastructure, subsea pipelines bear a high possibility of suffering damage. This could be the result of anything from equipment failure and corrosion to human error and natural causes,” says Peter Baker, Senior Product Manager – Subsea at Advanced Navigation.

“The future of subsea pipeline inspections lies within the advanced technology of professional underwater drones that prioritize user-friendly operation, ensuring reliability in challenging offshore environments. The integration of underwater drones has emerged as a transformative force in the oil and gas industry,” adds Mira Nagle, Marketing Administrator at Oceanbotics Inc.

Underwater drones are changing subsea pipeline inspections in the following ways.

How underwater drones are beneficial in subsea pipeline inspections;

1. Enhanced Mobility and Accessibility

Even in challenging environments, underwater drones provide unparalleled access to subsea pipelines. These drones can effortlessly navigate through intricate underwater structures, such as pipelines, thanks to their sophisticated propulsion systems and precise control mechanisms. Their minimized size permits them to arrive at bound spaces that would be difficult to reach by human jumpers, making it conceivable to examine every last bit of the pipeline. According to Mira, underwater drones present a user-friendly and efficient alternative to the challenges associated with traditional inspection methods. “These challenges include harsh underwater conditions, unsafe working environments, unreliable equipment and time-consuming operations, all of which ultimately result in increased costs,” she explains. Because of the increased access, thorough inspections are guaranteed, identifying potential issues before they become significant. “The demand for greater flexibility, maneuverability and scalability is driving underwater drones, or micro-AUVs, to become an increasingly popular tool for inspecting subsea pipelines,” Peter notes.

2. Visual Inspection in Real Time

The ability of underwater drones to capture high-definition images and videos in real time is one of their significant advantages. These drones provide inspectors with a clear and comprehensive view of the pipeline’s condition thanks to their powerful cameras and lights. Using a protection analyzer, the robot can survey the nature of the pipeline’s protection, recognizing any weak spots or harm. This visual inspection in real-time makes it possible to make quick decisions and take immediate corrective actions when needed.

3. Testing That Isn’t Destructive

Underwater drones provide a non-destructive testing method for subsea pipeline inspections. The infrastructure’s integrity can be jeopardized by invasive techniques like cutting into the pipeline or using intrusive probes in traditional ways. The traditional approach of sending a large construction vessel equipped with a work-class ROV is inefficient, expensive and labour-intensive,” observed Peter. “The answer to this challenge is smaller vessels that burn little to no fuel, remove humans from dangerous conditions and can be deployed on a large scale. Specifically in the offshore energy sector, scalability is pivotal to the effectiveness of any kind of operation,” he recommends. The risk of further damage to the channel is kept to a minimum with this non-destructive method, and the inspection results are guaranteed to be accurate and dependable.

4. Effortless Data Gathering and Analysis

Submerged drones smooth out the information assortment process during subsea pipeline reviews. Using a protection analyzer, these robots can accumulate essential information on the protection honesty of the pipeline, including estimations of opposition and protection breakdown voltage. This information is gathered progressively and can be examined promptly utilizing installed handling capacities or sent to a control station for additional examination. Underwater drones significantly shorten the amount of time and effort required for inspections by automating the processes of data collection and analysis.

5. Effortless Inspections

Large teams of divers, specialized equipment, and lengthy deployment times are all required for traditional subsea pipeline inspections, which can be prohibitively expensive. A less expensive alternative is using underwater drones. With their independent abilities, these robots kill the requirement for human jumpers and decrease functional expenses altogether. In addition, the capacity to efficiently carry out inspections in real-time and gather data reduces downtime and boosts overall inspection productivity. Peter points out that, the timely inspection of subsea pipelines is key to preventing damage such as oil spills and leakages. Typically, these inspections require either sending a well-trained human diver or using large and heavy work-class ROVs, however both methods have downsides. The first puts the diver at risk, which becomes greater the deeper they travel underwater. The second method remains suited only to large-scale operations and at suitable depth. “A common challenge industries face is when depths and other conditions are not favourable. For example, as the water becomes shallower or the environment more sensitive to larger vessels, complications arise in getting appropriately sized and maneuverable equipment into place,” he defines.

“Additionally, ROVs are costly to build and maintain, often requiring large, specialised crews to deploy and retrieve. They are also limited by the length of their tethers and the need for constant human supervision, impacting the frequency and scale of inspections,” Emphasized Peter.

6. Further developed Well-being

Due to the hazardous nature of the environment, subsea pipeline inspections place a high priority on safety. By reducing the dependence on human divers in potentially dangerous conditions, underwater drones significantly enhance safety. “Underwater drone represents a comprehensive solution that redefines the efficiency and effectiveness of subsea inspections,” highlights Mira. Operators can lessen the dangers of underwater inspections, such as the dangers of deep diving, decompression sickness, and adverse weather. Human operators can monitor the assessments securely while maintaining complete control thanks to these drones’ remote operation.

Conclusion

In conclusion, the improved access, real-time visual inspection capabilities, non-destructive testing methods, efficient data collection and analysis, cost-effectiveness, and increased safety that underwater drones provide have revolutionized subsea pipeline inspections. These drones can inspect the insulation of the pipeline without causing damage, ensuring the infrastructure’s integrity. Underwater drones are becoming increasingly important in ensuring the safety and dependability of subsea pipelines as technology advances, safeguarding our marine ecosystems and sustaining the global energy supply.